Versteckte Art Wool Composite Sheet Roll Forming Machine

$40000≥1Set/Sets

| Zahlungsart: | L/C,T/T,D/P,Western UnionL/C,T/T,D/P |

| Incoterm: | FOBFOB |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | Tianjin New Port |

$40000≥1Set/Sets

| Zahlungsart: | L/C,T/T,D/P,Western UnionL/C,T/T,D/P |

| Incoterm: | FOBFOB |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | Tianjin New Port |

Modell: XF1000/1200 EPS Rock Wool Sandwich Forming Machine

Marke: XF

Anwendbare Branche: Baumaterial Geschäfte

Out-of-Warranty-Service: Online-Hilfe, Ersatzteile, Video technischer Support, Feldwartungs- und Reparaturservice

Wo Können Lokale Dienstleistungen Anbieten (in Welchen Ländern Gibt Es In Übersee -Dienstleistungen Im Ausland): Keiner

Ausstellungsraum Standort (in Welchen Ländern Gibt Es Probenräume In Übersee): Keiner

Video Factory Inspection: Bereitgestellt

Mechanischer Testbericht: Bereitgestellt

Marketingtyp: Neues Produkt 2020

Kernkomponenten -Garantiezeitraum: 1 Jahr

Kernkomponenten: Plc

Alt Und Neu: Neu

Herkunftsort: China

Garantiezeit: 1 Jahr

Kernverkaufsargument: Leicht zu bedienen

Zertifizierung: ISO

Customized: Customized

Automatic Grade: Automatic

Transmission Method: Hydraulic Pressure

Voltage: 380V 50Hz 3Phases

Suitable To Process: Color Steel Plate

Thickness Of The Plate: 0.3-0.6mm

Width Of The Plate: 1000/1200mm

Machine Name: EPS Rock Wool Sandwich Forming Machine

Name: Rock Wool Sandwich Forming Machine

Machine Type: EPS Sandwich Forming Machine

| Verkaufseinheiten | : | Set/Sets |

| Pakettyp | : | Wir haben professionelle Techniker für das Laden Garantiert die Warenladung in Behälter ohne Schaden. |

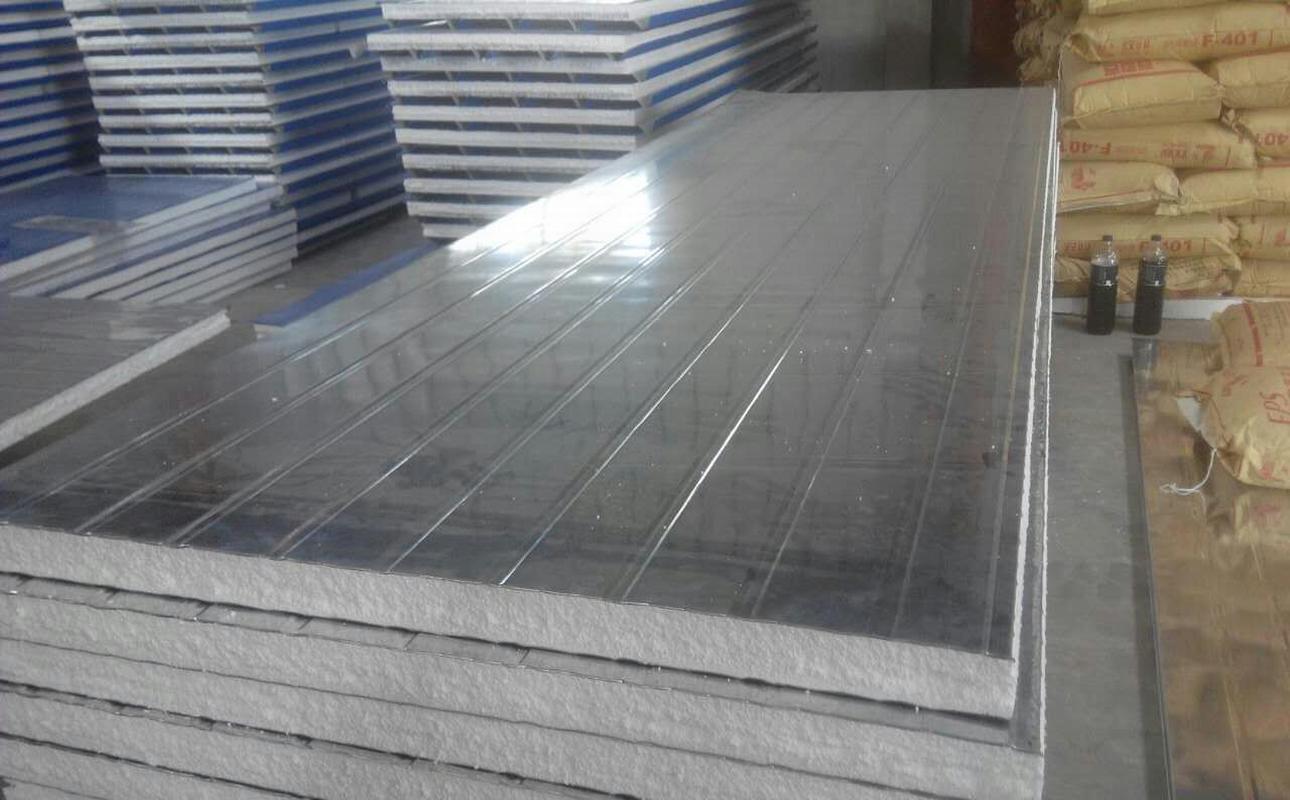

| Bildbeispiel | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Versteckte Art Wool Composite Sheet Roll Forming Machine

XF Sandwich Panel Formmaschine, Steinwolle Sandwich Panel Formmaschine, EPS-Steinwolle-Sandwich, das Maschine bildet

1. Geräte detaillierte Parameter

|

No |

Forming Machine Parameter |

|

|

1

|

Suitable Material |

Colored Steel plate, Galvanized board |

|

2

|

Width of the raw material |

1000/1200mm |

|

3 |

Total Power |

28KW |

|

4 |

Thickness of raw material |

0.3-0.7mm |

|

5 |

Thickness of Panel |

50-200mm |

|

6 |

Machine Length |

23500x2440x2450mm |

|

7 |

Weight |

9600KG |

|

7 |

Speed |

0-4m/min |

|

8

|

Voltage |

380V 50Hz 3phases |

2.Maschinenkomponente

|

Decoiler 1 It adopts coil holder with break device. 2 Loading capacity: Less than 6T 3 Width: 1200mm Roll Forming Machine 1 Main Frame: 300 H steel welding 2 Main Board:14mm 3 Shaft diameter:70mm 4 Roller Station:15row(Roller material 45# steel,roller surfaces polishing, hard plating) 5 transmission way: chain draive 6 Power:3KW 7 Feeding Device has pre-cutter 8 Size::7260X2050X670mm 9 Weight:About 3T Composite Part 1 This part including: Press rib, glue, heating, combine, slotting, ending and pneumatic move up and down. 2 Main machine adopts frequency conversion 3 Thickness adjustable by electric 4 Shaft of combine shaft:150mm, material is steel with rubber cover,to avoid any wear 5 Foam machine has 18 roller shaft, Rib rollers 6 rows 6 Transmission Way:Transmission and chain drive 7 :Reduction box power: Foam machine 3KW,with reduction box. 8 Main frame adopts square tube welding ,to make sure machine is stable and work smoothly Size:11.5X2.3X2.5m Electric system 1 Control: DELIXI low-voltage apparatus 2 Specification :programmable PLC and Delta PLC, double calculator, to insure the length 3 7inch touch screen ,failure warning Cutting Part 1 Non stop cutting , Pre-cutter can cut the length automatically 2 Pneumatic pressing device, control the cutter. And back to revious after cutting. 3 Cutting method: saw and cutter 4 Power:4KW 5 Size:1750X2520X1850mm 6 Weight:700KG. Feeding material of composite and roll forming part:1200mm Stacking Part 1 It adopts angle iron and square tube 2 Every stacker has 4 roller 3 Size; 3X1.3X0.8m 4 holding hook 1 piece, uncoiler core: 4 pieces, uncoiler holding part: 1 piece. |

Komponenten der Produktionslinie

|

No. |

set |

Name |

No. |

Set |

Name |

|

1 |

1 |

Uncoiler |

15 |

2 |

remain glue reciver |

|

2 |

1 |

Main composite machine |

16 |

4 |

Uncoiler core |

|

3 |

2 |

Cutting machine |

17 |

1 |

φ250milling cutter |

|

4 |

2 |

Transport table |

18 |

18 |

Adjusting block |

|

5 |

1 |

Roll forming machine |

19 |

25m |

Plastic foam |

|

6 |

1 |

foam holder |

20 |

20m |

Bubble wrap |

|

7 |

4 |

Holder pipe |

21 |

1 |

Pipe tip |

|

8 |

1 |

coil uncoiler |

22 |

1 |

seal gum |

|

9 |

1 |

ladder fence |

23 |

2 |

chuck |

|

10 |

1 |

coil hook |

24 |

2 |

filter screen |

|

11 |

6 |

dropper |

25 |

2m |

sponge |

|

12 |

3 |

Branking vane |

26 |

1 |

Fluorescent tube |

|

13 |

6 |

hopper |

27 |

6 |

Infrared ray heating tube |

|

14 |

4 |

Glue brush |

|

|

|

1. Wir haben professionelle Techniker für das Laden

Garantiert die Warenladung in Container ohne Schaden.

2. Transport: Maschinen benötigen einen 40 Fuß-Container zum Halten

3. Bitte geben Sie uns den nächsten port name, wir fragen versandkosten und arrangieren versand für sie

Wähle uns! Xianfa Roll Forming Machine Factory ist Ihr Vertrauen wert.

Wir machen Hochstandard-Rollformmaschine für den Export seit 15 Jahren.

Unsere Produkte wurden in mehr als 90 Länder und Regionen auf der ganzen Welt exportiert

Und hielt gute kooperative Beziehungen mit Kunden

Wir glauben fest an technologische Innovation und machen jedes Detail des Produkts perfekt.

Produktgruppe: Manufacturing & Processing Machinery> Baumaterialherstellungsmaschinen> Fliesenherstellungsmaschine> Sandwich Panel Forming Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.